Industrial automation: the advantages of optimized processes

Industrial automation is a rising trend that, after an unavoidable stop due to the global pandemic of COVID-19, has been regaining its role in Industry 4.0 strategies.

Talking about industrial automation may raise concerns about the future of the ‘human’ labor force, but it is anachronistic to imagine a future without automation and digitalization. The 4th Industrial Revolution is already here.

From assembling to storage and transportation: there are several applications of automation technologies in smart factories. And there are several advantages that can offer new business opportunities.

The advantages of industrial automation

Increased productivity

A robot doesn’t get tired and it can guarantee a constant level of high performance. It can repeat the same tasks infinite times (if it does not break down, of course). The production becomes more efficient and accurate and the margin of error can be reduced to the minimum. Workers won’t do repetitive and potentially dangerous tasks. New highly specialized profiles for programming, monitoring, and analyzing tasks will gain more value in the companies.

A more efficient organization

Thanks to robot programming, it is possible to schedule different tasks and avoid inactivity in production. Automation allows companies to optimize costs and time.

Reduce margin of error

The margin of error is an inevitable consequence of human activities. After long hours of work or even for a simple distraction, a worker can commit an error that can compromise production. Industrial automation reduces this risk. Machinery can make mistakes as well, but smart factories can perform constant monitoring, both on-site and remotely. In this way, anomalies and errors can be promptly detected.

A better security

Besides the reduction of errors, automated processes can reduce the risks of accidents at work. An increased production accelerates the working pace with heavier shifts and complex tasks. By using smart machinery, these repetitive operations can be delegated to robots.

A more reliable company

There is no doubt that an organized and efficient company, that maintains deadlines and delivery schedules, is more reliable for old and new potential clients. Business opportunities can grow with a smart company.

Valid support for decision-making processes

Thanks to AI technologies and Big Data, it is possible to predict trends and manage the workflow. Smart factories are able to take strategic decisions based on factual data and information. Robotic automation allows flexible production, which is the future of the global industry.

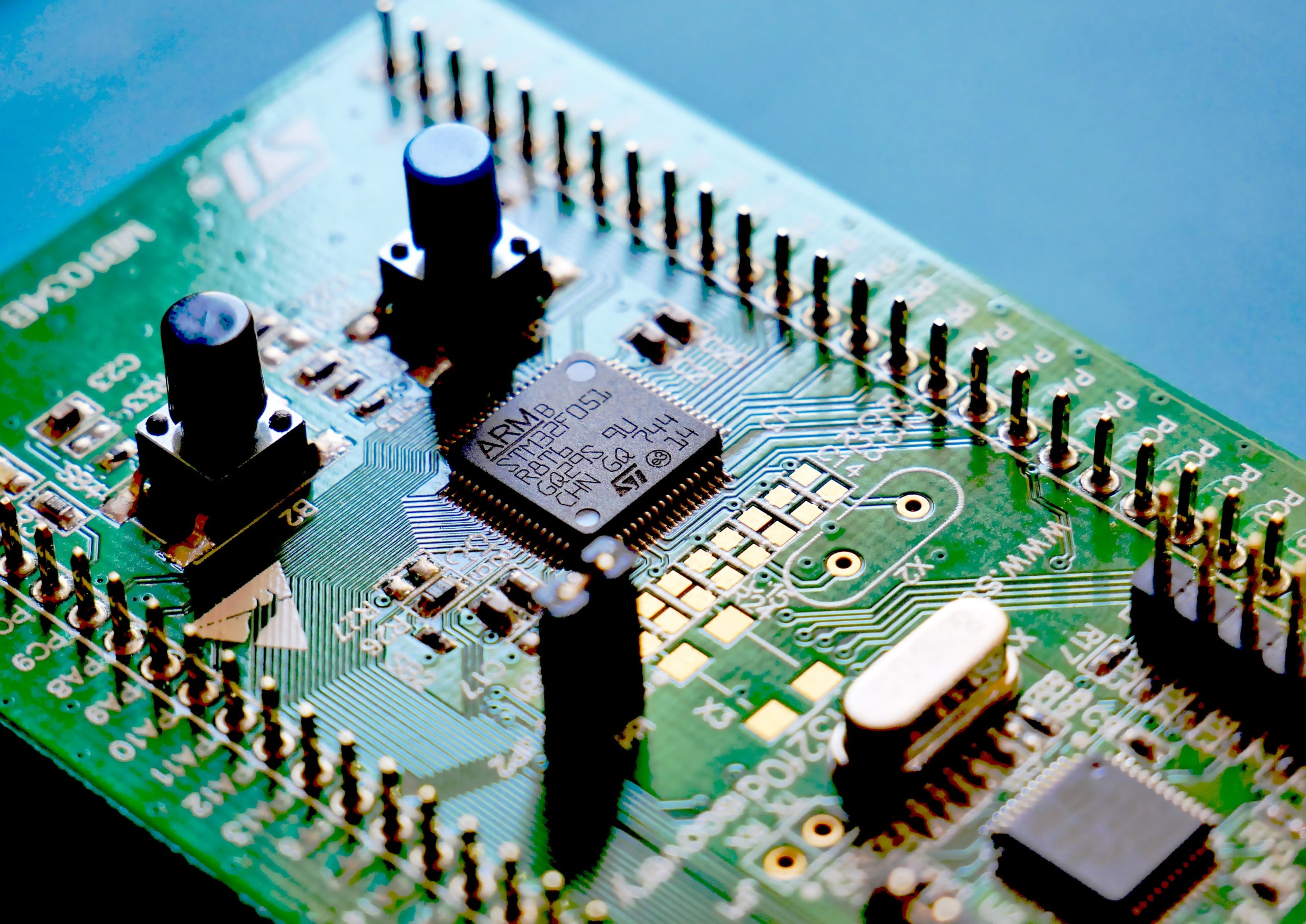

MAS Elettronica supports industrial automation

At MAS Elettronica we believe in the future and evolution of Industry 4.0, where automation represents an essential element to improve the industrial world. Every day, we support our clients to help them become more competitive and efficient.

Among our products for industrial automation, we present:

- SBC Mina: a single board computer aimed at sectors like industry, medical, and automotive, where robots manage different phases of production. SBC MINA is ready to use and can support a high volume of data;

- SBC Frida: thanks to the standard PICO ITX and SMARC 2.0, the single board SBC Frida offers modular solutions that can be adapted to every industrial sector.

Contact us for more information on MAS Elettronica solutions for industrial automation:

IoT and Ai for a more interconnected business

In the collective imagination, the Internet of Things and Artificial Intelligence technologies refer mainly to Smart Homes, vocal assistants that turn on and off lights, smart household appliances, and all those apps that make users’ lives more interconnected. But IoT and AI are also the core of Industry 4.0, where technology does not substitute only manual labor but manage and optimize processes to improve performances and monitor businesses.

AI and IoT technologies can improve a business, changing the way we have always perceived a workplace. IoT has allowed digital transformation: thanks to it, devices can collect huge amounts of data in real time and use Big Data to bring benefits to the business.

AI and IoT benefits are numerous: in this article, we will show some of the advantages of having a more interconnected and digital business.

-

Better Efficiency

Optimizing processes, costs, and raw materials storage is one of the biggest benefits of implementing Artificial Intelligence into a business. Thanks to IoT and AI it is possible to automate processes in all the different phases of a product work chain: from construction to the final delivery. Thanks to the collected data, machinery can monitor all the steps and operations, identify departments where the request is higher and propose efficient solutions to optimize production. When using AI technologies, it is possible to avoid shortage or overstocking of raw materials and have more organized and efficient warehouses.

-

Cost Reduction

The Internet of Things technologies can bring important benefits in reducing costs, as well. It is necessary to overcome the initial skepticism driven by the requested investment for the digital transition of the business. The return on investment will be tangible because with IoT it is possible to reduce workforce or employ it in more efficient tasks for the business. It is also possible to perform predictive maintenance to reduce machinery stops and consequently production. Using sensors on machinery, it is possible to analyze data on usage, and for example calculate components' wear and stock quantities, or receive alerts on malfunctions to promptly intervene.

-

Improve the Customer Experience

It is difficult to imagine today a delivery without a tracking code, a house without at least one device or appliance connected to a mobile phone. New technologies have simplified our lives, improving our experience as consumers of several businesses. Thanks to machine learning, companies can deeply know customers’ habits and preferences, while IoT apps can monitor in real time a product or service usage. Therefore it is possible to create customized products that can address different needs. IoT apps can alert companies of a service malfunction that can affect customers and, if possible, try to solve it in a short time, likewise predictive maintenance.

Mas Elettronica, for a more interconnected company

Mas Elettronica has always worked to help businesses into the digital transition, offering products and strategic advice for the Internet of Things and Artificial Intelligence applications. Among our products, we would like to highlight SBC Frida - IMX8M, a single board computer based on core Arm A53 multicore NXP i.MX 8M. SBC Frida has an integrated microcontroller for Low Power app and TPM security module to protect the integrity and authenticity of your embedded system.

Contact us for more information on MAS Elettronica solutions for IoT and AI applications:

Custom Carrier for a winning time-to-market business

Custom Carrier solutions are a good way for a time-to-market and competitive business: a unique approach to address the needs of every company and enter the market at the right time with the right price. This is the great challenge every innovative business should take to be ready to achieve success.

Starting from a standard system that supplies the base processor, it is then possible to adapt it following the technical and technological requirements of the specific project. The custom solution has personalized features on the carrier board without slowing down design and production processes. A modular design allows one to customize a board with the required I/O, reducing time and costs compared to a full-custom project.

Among the advantages of a modular Custom Carries solution, we can list the flexibility. If a project's requirements change (for example more complex tasks or performances), it won’t be necessary to change the entire system but only a single module. A custom solution allows the optimization of energy consumption and consequently the economic and environmental impact of a product or process.

A full-custom design has the advantage of being customizable but it is more expensive, it requires more time to be developed and specific maintenance. Custom Carrier solutions can offer cost-saving and rapid personalization, allowing also smaller production.

MAS Elettronica custom solutions

Thanks to its extensive experience, MAS Elettronica offers several embedded solutions and custom carrier solutions. MAS can provide Single Board Computers that are compact, low-power, and completely modular, like SBC Frida i.MX 8 M, based on core Arm A53 multicore NXP. Frida SBC has an integrated low-power microcontroller, ideal for low-power applications, and the security TPM module to protect the integrity and authenticity of the embedded system.

MAS Elettronica follows all the steps of a project: from the brief to the design, from the prototyping to the production and maintenance. Our clients’ projects are our projects, too. We work together to find the best, winning, and time-to-market solution.

Contact us for more information on MAS Elettronica solutions:

Cyber Security, how to choose the most secure hardware

When discussing cyber security, the focus is usually on the best software to avoid malware and cyber attacks, but choosing good hardware should be at the top of the priorities because it can determine a business level of security. Cyber attacks are constantly growing and it is estimated that they can cause damage up to 6 trillion dollars every year. To block this risk businesses must invest in hardware that can guarantee security. Generally, hardware is less vulnerable compared to software for several reasons, like reduced accessibility or greater difficulty of hacking.

However hardware is not 100% safe, so here are some tips on how to select the best hardware for secure solutions.

- Know the risks to avoid them.

First of all, it is necessary to have a clear idea about the risks that a business can encounter, like the exchange of sensitive information. In that case, it is fundamental that the hardware is capable of supporting a high load of encrypted data, and at the same time, it won’t slow down networks and processes. - Verify the compatibility.

Before changing any hardware, it is important to verify that it is compatible with apps and systems a business is using or will use shortly. - Train your workforce.

Even good hardware can be a threat if it is not used correctly. The majority of cyber attacks could be linked to some form of negligence like sharing information, sharing passwords, or the wrong use of devices. It is, therefore, necessary to have a policy for all the users and organize training to be always updated on new systems. - Secure your work environment.

To avoid cyber attacks it is better to be protected from actual attacks, like thefts or tampering. It becomes fundamental to have protection systems in the work environment to prevent thefts, fires, floods, and other possible damages. - Do not forget the old ones.

Replacing hardware with a newer one is a good choice, but better not to forget the old devices and machinery that could be used for cyber attacks. - Use TPM modules.

To protect hardware it must be designed using a TPM, a Trusted Platform Module, a processor that can guarantee integrity to embedded systems and can encrypt information, data, and operations.

MAS Elettronica secure hardware against cyber attacks

For better security of embedded systems, we use the new generation TPM 2.0, which can offer major flexibility, support the most recent algorithm, and comply with international standard ISO/IEC 11889:2015.

Our single boards Frida SBC IMX8M and SBC Mina IMX8M are designed with the TPM 2.0 module.

Contact us for more information: