SERVICE OF HARDWARE DESIGN

Thanks to a personalized hardware design it is possible to modify or replace some components according to the best price and availability on the market. MAS Elettronica’s solutions mirror the client necessities to fully optimize the performances, the cost, and the due time.

Architectures in use:

Arm® Cortex®, Arm9™, Arm11™, Arm A53™, Arm A72™, Arm A7™, Arm A9™

IBM PowerPC ®

NXP ColdFire®

Xilinx FPGA Spartan and Lattice FPGA Video cores.

Our involvement

The customized hardware design of a system involves different phases to reach a complete and optimal solution.

Definition of the systems architecture

Thanks to our knowledge of the design and of the technologies of production and to the experience of our partners, we offer the best technical solution to satisfy the needs of our clients respecting the requisites of performances, costs and power consumption.

Electronic schematics design

In this phase, we use the best CADs on the market, we choose the components on the basic parameters of MTBF, availability and cost, we control the rates of availability and costs, we observe the criterions of projecting as the advanced power management and the signal integrity by design.

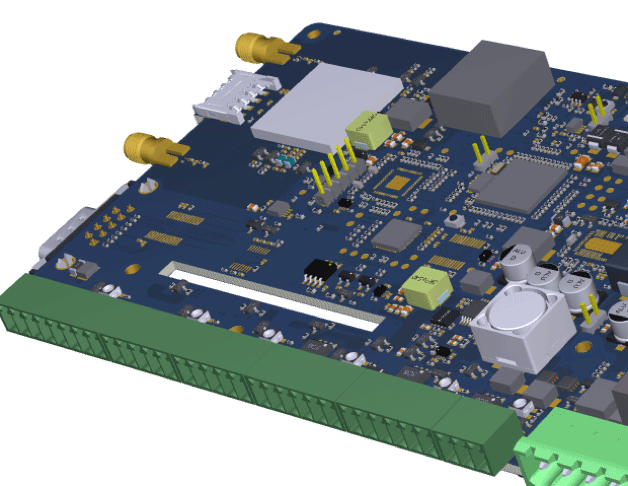

PCB design

This phase is developed in collaboration with our partners and it follows all the aspects of the generation of a printed circuit: the 3D mechanic analysis, the thermal analysis of the system, the analysis of the impedance and integrity and the Design for Manufacturability (DFM), to project the mass production

Rapid Board Prototyping, Test and integration

Thanks to our technological partners we can offer a service of rapid prototyping of the designed boards.

The prototype test is realized by our technicians using high-tech tools. A detailed report on the tests results is sent to our clients for a confrontation.

The integration of the prototype on the system of our clients consists in the final activity before the trials of pre compliance.

Pre compliance testing

After the phase of prototyping/preseries we offer a service of EMC pre-compliance of the boards and of the whole system of the client. Here there are some tests we make:

- Test of emission following the regulations and levels of acceptance of the sector of application.

- Test of immunity conducted and emanated following the rules and levels of acceptance of the sector of application.

- Test of temperature and duration.

- Some other tests such as: Vibrations, Humidity, etc.

In our laboratories we project a customized hardware which is able to transform the ideas of our clients into solid projects and accelerate the development of their products.

Anyway to project a software able to offer high performances, it is necessary the existence of a hardware which could guarantee the best performances. For this reason, it is fundamental that the companies are continuously looking for the best solution, especially during this delicate historical moment and the right solution could simply be a hardware customized design.

SOFTWARE AND FIRMWARE DESIGN

The usage of the technologies extensively consolidated allows MAS to work in a fast and safe way, as well as to deliver a solid and well tested product. Simplicity and portability are the focus of our work on the graphic interfaces which are part of our products. Software solutions from the Board Support Package (BSP) till advanced user interfaces.

PRODUCTION

MAS Elettronica has chosen to entrust the management of the production of its cards to Italian partners who are considered leaders on the market. Mas technicians and our partners take care of the entire productive process even observing the minimum details: from the assembly of the productive process, to the tests (ICT and functional) of the cards; form the process of labelling, that of quality supervision, till the packaging of the systems.